How long do you need to wait before applying lamination film to your printed sheets?

How long do you need to wait before applying lamination film to your printed sheets?

I am often asked if there is a quicker way to turn around a laminating job. This seems to be driven by the online print trend, and there is an expectation nowadays of a next day delivery service. It is easy to log onto a shopping channel and order goods with one click, so why not print and lamination? Well mostly its working as inks are becoming faster drying and machines have better drying components, however there are still many lifting problems with solid colours on spines, particularly on perfect bound books or heavily creased folds on thicker materials.

A regular question I am asked is – can you get a better or stronger adhesive that will allow to laminate faster? A common misconception is that when film lifts, it is a result of poor adhesion. It is in fact exceedingly rare to find this. Adhesives are made in batches, and it is easy to trace back and test. If adhesive does fail, it usually happens during the lamination process and an operator will see this during the standard QC checks. Stronger lamination adhesives can be manufactured; however, they won’t bond with wet inks if the ink is still “out gassing”.

Out gassing is a crucial part of the printing process. Typically, print should be left between 24hrs and 36hrs to allow the solvents time to escape and evaporate away from the pigments in the ink. Oxidising inks absorb oxygen from the air; the oxygen reacts with substances in the ink (usually drying oils such as linseed oil), which causes the ink to undergo polymerisation and results in the ink hardening into a solid film. This can take longer depending on the ink saturation (a more solid ink can take more time to dry out.) and even when inks appear dry on the surface, it is often just a crust layer on top of the ink (similar to an under baked cake). The ink isn’t fully dry until all the solvent gasses have evaporated.

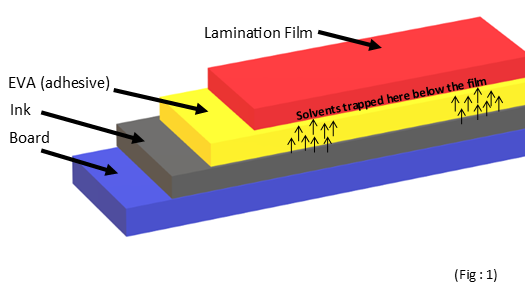

If the printed sheet is laminated before this process has fully taken place, the gasses created during the drying process cannot find their way out through the normal course of evaporation and get trapped between the film and the board. (see fig:1) Over time, (sometimes days or weeks later) the solvents can cause a chemical reaction with the EVA (Adhesive). The reaction makes a weaker bond between the ink and the EVA and can cause the film to lift away from the ink. In severe cases it will form tunnels under the lamination film (sometimes called piping) It can also cause colour change in the ink, as once lamination has taken place it essentially stops the drying process.

De-lamination is more common in areas that are likely to stretch the laminate film. It can happen on creases or folds in the material. If the bond has been damaged, the film will pull away more easily due to any stretching or lateral movements of the sheets. It is also more common in the darker solid areas where there is more buildup of ink and it has needed more time to gas out. On perfect bound books you can usually see it only lifting in the darker areas of the spine. There is a simple test to prove this. Compare the areas that are lifting with the white unprinted areas in the gullies or grip edges of the effected sheets. If the lamination sticks well to unprinted areas, it will be apparent that the weak bond is between the ink and the film not the board and the film, which then validates that the adhesive is working when not corrupted by wet ink.

Even if you own your own laminating machine, there are no short cuts and considering the recommended waiting times between print and lamination, using next day local lamination services such as Ultra Finishers are still a fast option and due to their vast experience in this kind of work, they can often save many own goals from print that is too wet to laminate.

Still thinking about cutting corners? My advice would be that it’s a good idea to consider the ink coverage and the binding process before deciding how long to wait before laminating. We are always here at Ultra to answer your questions and can help advise if you are unsure.