What is Foil Blocking?

Foil blocking is a process we use at Ultra Finishing to embellish print. It was thought historically to have been invented by the ancient Egyptians for decorative purposes. They were said to have spent hours hammering gold into rolls of parchment so it could be transferred later onto stamped designs using heat and pressure. They were literally printing with gold and it would have looked amazing!

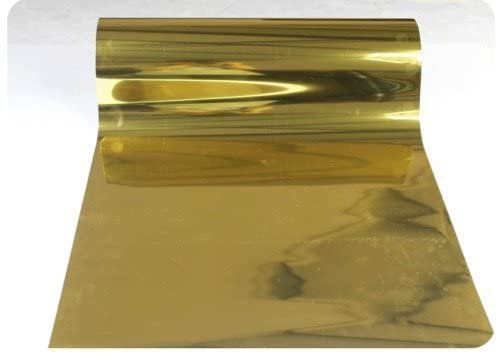

To create the same effect in modern times, we use a metallic gold film which is laminated to a heat releasing substrate. This is now available in thousands of different shades and even coloured or clear holographic effects.

Once decided on a colour or holographic effect, the artwork is sent to a specialist die maker. Here the design is copied onto a magnesium block. If you think back to your school art days, you probably dabbled in potato printing? So, in simple terms die making is similar to cutting out a design in a potato, only now a special etching machine is used to engrave the image onto a metal block so it can be used as a pressing tool called a die.

Once the die is made it is carefully positioned on a machine bed to the exact area of paper to be printed upon. Then as the paper passes through the machine and over the foil, it is simultaneously pressed down onto the heated die and the foil is released and transferred onto the paper leaving the design image area only on the paper – (Only the heated and pressed areas transfer, the remainder of the roll of foil is collected on a reel and recycled)

Here are some answers to the most common questions we are asked by our customers when placing orders for this kind of work.

- We use magnesium dies as standard although copper dies are available, and our production staff will advise you how to achieve the best results.

- Full range of colours are available, and we can provide a swatch for you to work from.

- For work where UV varnish is not suitable, we have clear foil which gives an alternative effect to varnish.

- Lead times can vary depending on the intricacy of the project. Our production staff will advise when you are booking in work.

- When quoting you will need to tell us the following:

- Foil Colour

- Foil Area dimensions

- Sheet layout – (How many up)

- Sheet quantity

- Where possible, try to avoid reversing print out of foil area.

- When presented with certain fine detailed foil blocking work, our production staff may advise you to purchase copper dies. This will only be suggested if we think the quality of your work would be impaired using magnesium dies.

- We advise customers to leave the foil blocked work 24hrs before the next process.

- Embossing and debossing depths are dependent on several variables. It is important that you discuss expectations with our production team so we can advise on your specific projects before your board is chosen.

- Each substrate will allow a different depth level.

- This can vary again if printed, depending on depth of colour.

- Substrates split at a certain level and each material has its own surface strength that will give way at some point.

- As standard we apply a split test at the make-ready stage. We increase packing gradually until the board splits, then remove it until we know we are embossing/debossing at the optimum level.

- We ask you to provide a sample flat sheet if the job has been produced before.

- Where uncoated boards are used, inks need to be dry before any foil is applied. Please allow up to 48 hours between printing and foiling.

- Fine detail work does not emboss well, particularly on thicker stock. A proof is recommended.

- Our customers are welcome to press pass any work if required

- Please follow this link to FIND OUT MORE